FAQ - SAP Certified Application Associate - Production Planning Manufacturing with SAP ERP 6.0 EHP7

Here we are listing all SAP Certified Application Associate ? Production Planning Manufacturing with SAP ERP 6.0 EHP7 Frequently Asked Questions. These are mostly asked when appearing for Production Planning Manufacturing with SAP ERP 6.0 EHP7 Exam. Once you go through it, this will help you to better prepare for exam.

What are the total questions for the C_TSCM42_67 exam?

80 questions

What is the cost of C_TSCM42_67 exam or Production Planning Manufacturing with SAP ERP 6.0 EHP7 certification fees?

200 USD if you purchase CER001 (1 attempt) and 500 USD if you purchase CER006 (6 attempts).

What is the passing percentage for Production Planning Manufacturing with SAP ERP 6.0 EHP7 exam?

63 Percentage

What is the duration of exam C_TSCM42_67?

180 mins

What are the topics covered in exam C_TSCM42_67?

- Material and Capacity Requirements Planning, (> 12%) => Characterize production-relevant planning functionality. - Material Requirements Planning (PP-MRP), (> 12%) => Explore material requirements planning functions. - Production Orders Advanced (PP-SFC), (> 12%) => Configure production order functionality. - Lean Manufacturing (PP-REM, PP-KAB), (8% - 12%) => Outline the highlights of repetitive manufacturing and kanban. - Master Data (LDM), (8% - 12%) => Set up master data for production planning and manufacturing. - Production Orders Basics (PP-SFC), (8% - 12%) => Apply production order functionality. - Application Overview and Background, ( 8%) => Characterize the interplay of master data, planning, ATP, and production functionality. - Basics on SAP Business Processes (E-Learnings), ( 8%) => Outline the scope of SAP SCM business processes. - Process Orders (PP-PI), ( 8%) => Identify specific properties of process orders.

What books/courses needs to be read for exam C_TSCM42_67?

- SAP Learning hub PLM114 - Basic Data for Manufacturing and Product Management pdf

- SAP Learning hub SCM130 - SAP ERP Planning and Manufacturing Overview pdf

- SAP Learning hub SCM240 - Production Planning in ERP pdf

- SAP Learning hub SCM365 - Capacity Evaluation & Leveling in ECC pdf

- SAP Learning hub SCM300 - Manufacturing Overview pdf

- SAP Learning hub SCM310 - Production Orders pdf

- SAP Learning hub TSCM40 - SAP ERP Planning/Manufacturing I - Academy pdf

- SAP Learning hub TSCM42 - SAP ERP Planning/Manufacturing II - Academy pdf

Where to get Study Material and books for C_TSCM42_67?

You can check here the learning journey provided by SAP here SAP Certification Hub.

In how many languages C_TSCM42_67 exam available?

German, English, Japanese

What is the level of Production Planning Manufacturing with SAP ERP 6.0 EHP7 exam?

Associate

What is the process to register C_TSCM42_67 exam?

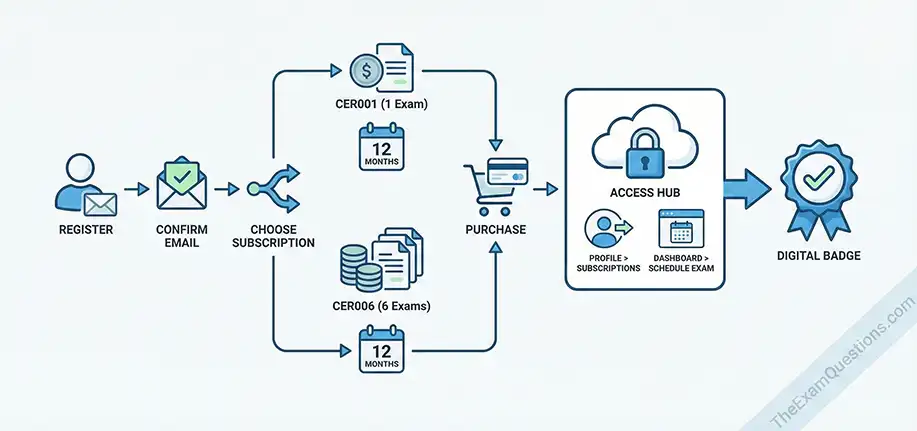

- Go to training.sap.com and register with your E-Mail id.

- Confirm your email address and finish the registration.

- If you are planning to take only this exam, then you need to buy for Single attempt subscription which is CER001. CER001 giver 12 months period in which you can schedule the C_ABAPD_2507 exam.

- Search for product CER001 on SAP website and add it to cart and do the checkout.

- If you are planning to do multiple SAP certifications, then you should consider buying CER006 product. CER006 also gives 12 months period in which you can schedule maximum 6 exams.

- Once you have purchased either CER001 or CER006, you will get access to SAP certification hub.

- Click on your profile icon and select "Access purchased Subscriptions":

- Go to SAP certification hub. click on "Exam Dashboard". Next, click on "Schedule an exam" and you are good to go.

- Successful completion will make you receive an SAP Certification digital badge for your accomplishment.

How is the exam conducted?

SAP C_TSCM42_67 Certification exam is remotely proctored via a webcam on your PC or laptop, and you can schedule your exam 24/7 via Certification Hub.

Do I need to go someplace to take the C_TSCM42_67 exam?

No, exams are available online 24/7 and each exam is proctored remotely. You can take exams anywhere in the world as long as you have an Internet connection and a laptop or desktop computer with a webcam.

Do I need to be alone to take exam?

Yes, phone should also be switched off. Your exam supervisor or examiner will ask you to rotate your webcam around the room prior to beginning your SAP Certification exam. Please ensure the area contains only permitted items approved by your exam supervisor. Whiteboards and bulletin boards must be cleared, erased, or covered, unless they are facing away from you. All cell phones, tablets, and other communication or recording devices must be removed from the computer area.

Can I take SAP C_TSCM42_67 Certification exam on a tablet computer?

No, tablets are not supported.

What do I receive after successful completion of exam?

Successful examinees receive an SAP Certification digital badge for their accomplishment.

What is the benefit of taking the exam?

- Gain a highly recognized accreditation of excellence.

- Differentiate yourself in the labour market.

- Validate your skills to execute with confidence.

- Possibility to attain higher wages and billable rates with a highly valued credential.

Can I retake for Production Planning Manufacturing with SAP ERP 6.0 EHP7 exam, if fail?

You can attempt C_TSCM42_67 exam 2 more times. If in worst case, you still could not clear the exam after 2 times, then you will have to wait for next version of exam to arrive.

What topics are covered in Book SCM240 (Production Planning in ERP)?

- Overview of Production Planning in SAP ERP

- Outlining the Supply Chain Planning Process

- Outlining the Core Production Planning Process

- Demand Management

- Outlining Demand Management

- Planning Make-to-Stock Production Without Consumption Logic

- Planning Make-to-Stock Production with Consumption Logic

- Planning Make-to-Order Production Without Consumption Logic

- Planning Make-to-Order Production with Consumption Logic

- Using Assembly Processing in Make-to-Order Production

- Applying Demand Management Enhancements

- Analyzing Availability Checks

- Material Requirements Planning Execution

- Outlining Material Requirements Planning

- Setting Up the MRP Prerequisites

- Executing the MRP Run

- Setting Up the MRP Run

- Planning MRP Interactively

- Applying Firming Mechanisms

- Technical Processes of Requirements Planning

- Calculating Net Requirements

- Applying Buffers in Net Requirements Calculation

- Calculating Lot Sizes

- Selecting Procurement Types

- Setting Up Basic-Date Scheduling

- Setting Up Lead-Time Scheduling

- Selecting BOM and Routing

- MRP Results Processing and Evaluations

- Comparing an MRP List and a Stock/Requirements List

- Applying the Planning Table

- Identifying Exception Messages

- Applying Additional Evaluation Aids

- Additional MRP Processes

- Applying Master Production Scheduling (MPS)

- Setting Up Long-Term Planning

- Executing Long-Term Planning

- Analyzing Multi-Site Planning

- Setting Up MRP Areas

- Applying MRP Areas

What topics are covered in Book SCM365 (Capacity Evaluation & Leveling in ECC)?

- Evaluation of capacity loads using reports in ECC

- Evaluation of capacity loads using reports using BI

- Navigational Skills of Tabular and Graphical Planning tables

- Detailed understanding of Capacity Leveling functionality (Strategy Profile)

- Modeling Down time Scenarios

What topics are covered in Book TSCM40 (SAP ERP Planning/Manufacturing I - Academy)?

- Creating and managing master data:

- Material master

- BOM

- Classes and characteristics

- Documents

- Overview of variant configuration

- Work centers and routings

- Production resources

- Changes with and without history, and mass change processing

- ERP production planning:

- Demand management

- Planning-based MRP

- Planning strategies for make-to-stock and make-to-order production

- Implementing requirements planning

- Processing of MRP results and additional MRP processes

What topics are covered in Book SCM310 (Production Orders)?

- Introduction to Production Orders

- Outlining SAP Supply Chain Management

- Outlining Production Orders

- Applying Production Orders in Supply Chain Management

Tags:

C_TSCM42_67 FAQ | C_TSCM42_67 detail | C_TSCM42_67 study material

Disclaimer: This content is an independent study aid and is not affiliated with, endorsed by, or sponsored by SAP SE. All logos, trademarks, exam codes, and product names mentioned are the property of their respective owners. No real exam questions or SAP-proprietary content is used in this article. Only SAP's publicly available information is collected to guide the exam takers accurately.